Internet of Things (IoT) is becoming one of the most valuable innovative technologies in the steel industry, bringing about major changes in production, management and operation processes. Connecting devices and production processes via IoT is helping businesses increase productivity, enhance management efficiency and optimize resources.

Definition of IoT

Internet of Things (IoT) is a network of devices connected to each other via the Internet, allowing the collection and exchange of data in real time. In the steel industry, IoT plays a role in linking sensors, machines and management systems, supporting the optimization of operational efficiency and saving resources.

How to Apply IoT in the Steel Industry

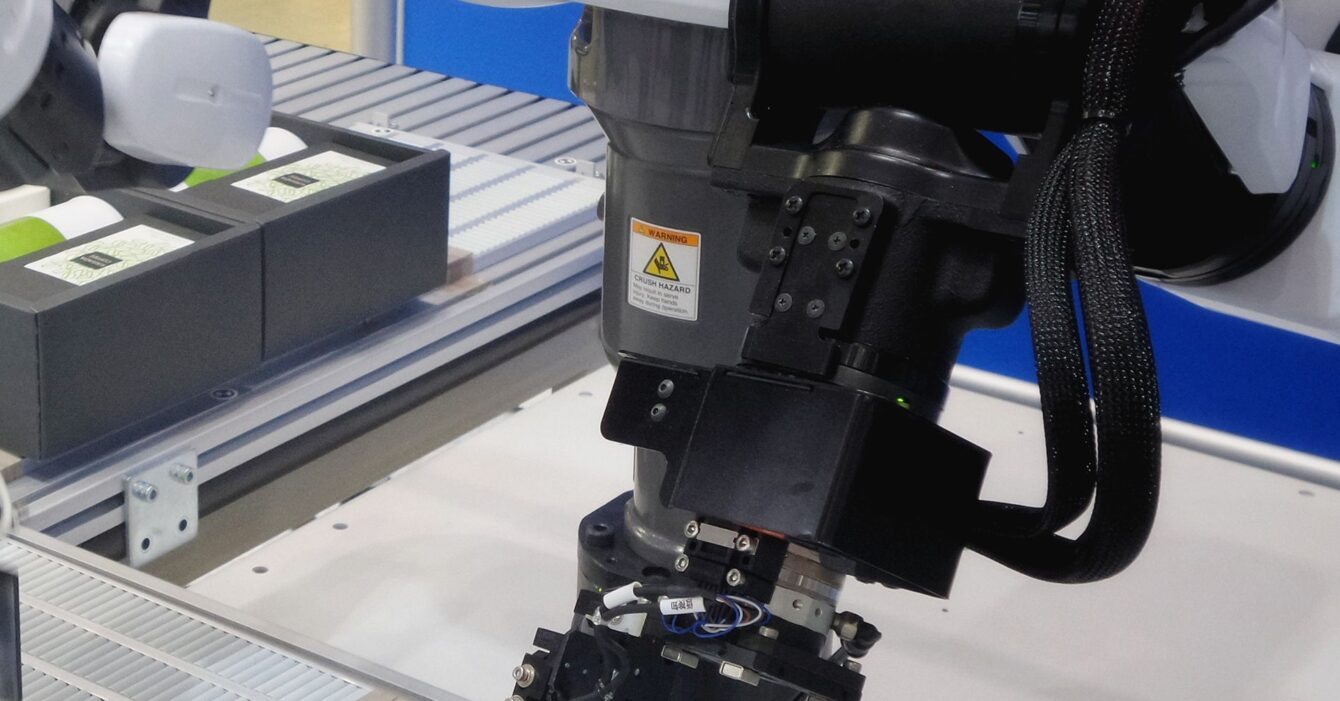

- Smart sensors:

IoT sensors are used to monitor temperature, humidity, pressure and vibration in equipment, allowing for early detection of problems. - Smart energy management:

IoT systems help optimize energy use in production lines, minimizing waste and costs. - Self-Monitoring Machines:

IoT-enabled devices are able to automatically check their operating status, detect errors, and send alerts to maintenance teams. - Predictive Analytics:

Data from IoT helps predict when to maintain or replace equipment, reducing downtime and improving productivity.

Outstanding IoT Technologies

- Sensors from Siemens: Help monitor and optimize temperature and pressure in the furnace.

- SCADA system: Incorporates IoT to collect real-time data from multiple sources.

- Schneider Electric’s EcoStruxure software: Efficiently manage energy in the production line.

- Smart Camera:Monitor and analyze production line data to detect abnormalities.

Benefits of IoT

- Increase efficiency:

Optimize production lines and save costs. - Reduce operating costs:

Detect errors in time, reduce emergency repairs. - Improve workplace safety:

IoT alerts you to potential hazards such as high temperatures or toxic gases. - Improve competitiveness:

Businesses that adopt IoT are often quick to adapt to the demands of the international market.

Things to Keep in Mind

- Investment costs:

IoT requires a large initial investment to deploy infrastructure and equipment. - Data security:

Connecting many devices creates the risk of cyber attacks. - Human resource training:

The team needs to be thoroughly trained to use and maintain the IoT system. - Scalability:

Ensure the IoT system is flexible and scalable as the business grows.

Conclusion

IoT not only helps steel companies achieve higher efficiency in production but also lays the foundation for sustainable competition in the era of industry 4.0. With outstanding benefits and development potential, IoT is a necessary solution for businesses that want to optimize and lead the industry.